We strive to be your preferred packaging machinery manufacturer, no

matter how challenging and unique your parts are –

we'll handle it. Who is Sunrise Corporation? Sunrise - Company Profile.pdf Engineering case of sunrise filling machina .pdf

Sunrise company was founded in 2009, headquartered in Jiangsu, China. As

early as the beginning of 2000, the company has been committed to

the combination of factory automation and factory intelligence, and

constantly absorbing high-end professional and technical talents in

the industry. Combined with their years of industry experience in

filling and capping aseptic and non aseptic environments, packaging

systems.

we offer you, our customer, with unmatched technology, quality,

innovation, customer service and unrivaled experience for your

automated requirements At present, the company is a

wholly-owned enterprise: Sunrise Intelligent Equipment Co., Ltd.,

Siyang Chida import and export trade Co., Ltd., Langfang sunrise

Packaging Machinery Co., Ltd.

The rising sun We are a high-quality, highly educated and

high-quality staff team, full of unity and innovation spirit and

our talented and knowledgeable partners (many of whom have more

than 20 years of experience in the industry), bring you advanced

equipment, we provide R & D, product design, manufacturing,

pre-sales and after-sales services to help you to implement the

project and achieve your goals. Inspiration and innovation are what

our engineers are good at.

Our company constantly improves the design process and our product

line, so we will meet your unique needs in the simplest way - help

reduce downtime, provide higher overall equipment efficiency,

reduce total cost of ownership and maximize efficiency

We recognize your needs and use original, resourceful ideas with

worldleading technology to unravel them. China Sunrise Intelligent

Equipment Co., Ltd company profile OUR PROMISE TO YOU

Positive Experience. We strive to make a positive experience with

consistent, dependable project management and transparency.

Innovation and Customization. Every customer is different and has

different needs. We specialise in bringing you innovative ideas,

solutions and technology so you'll bring your product to the market

faster. Dependability and Longevity. Consistently deliver reliable,

enduring, well built custom and standard products. Unrivaled

Customer Service. Whether it’s replacement parts or emergency

service, we've you covered with our experienced team. China Sunrise

Intelligent Equipment Co., Ltd company profile SERVICE What we will

do: The company's business mainly covers neutral beverages, acidic

beverages, sparkling beverages, wine, water, oil, canned foods ,

condiments, medicines and other equipment and related supporting

equipment. The company's professional sales, technical and

engineering teams can provide products to customers Onestop

professional services like shape design, beverage product formula,

plant layout design, process design and consultation, equipment

design and production, installation and commissioning.

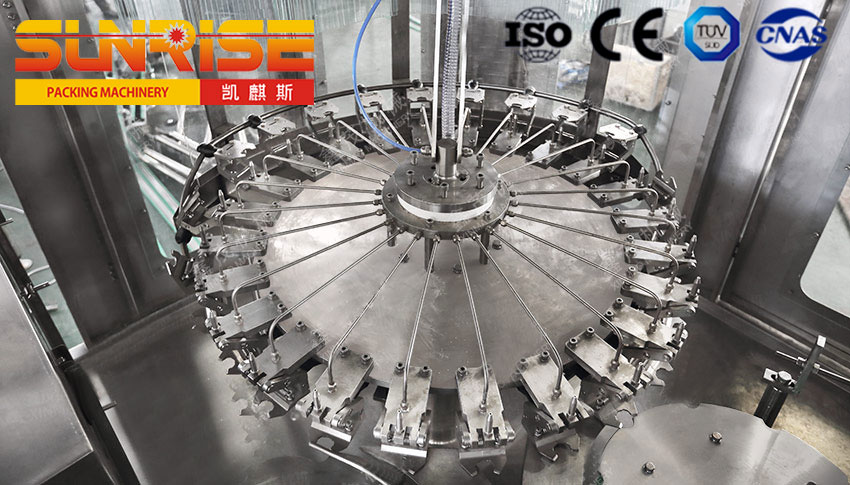

At present, the company's main assembly line series include:

█PET aseptic cold filling assembly line

█Can/Canned Food assembly line

█Glass bottle food and beverage assembly line

█The main products of pet water / beverage production line include:

water treatment system, pre blending system, pet aseptic cold

filling line related equipment, can / can production line related

equipment (mainly including automatic unloading machine, filling

and sealing machine, automatic cage loading and unloading machine,

robot encoder, automatic packing machine, etc.), special products

of Babao porridge production line (automatic Babao porridge capping

machine, automatic packing machine, etc.) Dynamic longan totalizer,

automatic lotus seed totalizer, etc.), glass bottle beverage line

related equipment, pet water / beverage production line related

equipment (including drinking water filling, medium temperature

filling, ultra clean filling, blow molding filling and spinning,

etc.).

The company's products have excellent material selection, reliable

performance and strong adaptability, which greatly improves the

automation degree and scale of the whole production line

;

OUR PROMISE TO YOU

- Positive Experience.

We strive to create a positive experience with consistent,

dependable project management and transparency.

- Innovation and Customization.

Every customer is different and has different needs. We focus on

bringing you innovative ideas, solutions and technology so you can

bring your product to the market faster.

- Dependability and Longevity.

Consistently deliver reliable, enduring, well built custom and

standard products.

- Unrivaled Customer Service.

Whether it’s replacement parts or emergency service, we have you

covered with our experienced team.